Pick-by-Light systemns "Made in Germany"

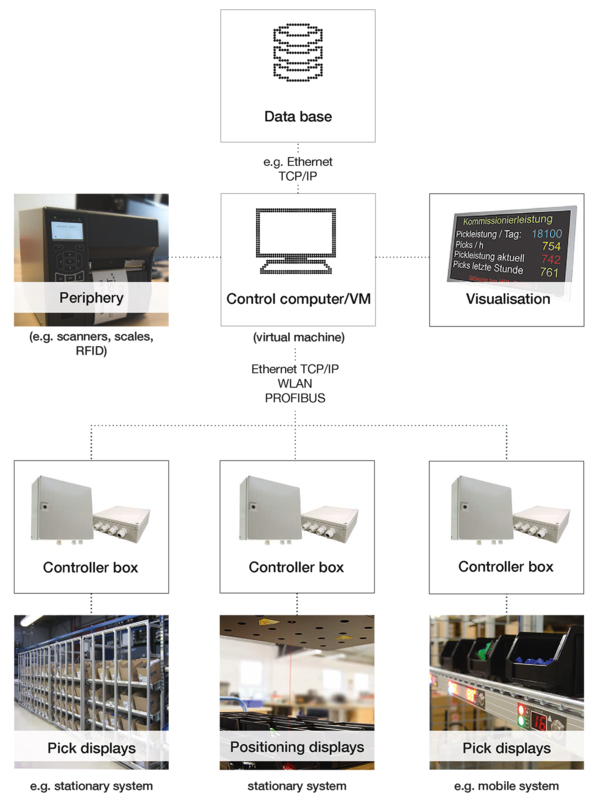

microSYST is developing and manufacturing order picking systems according to customer‘s requirements. We offer a suitable order picking system for every requirement, which can be flexibly and easily integrated into already existing systems such as ERP or MES systems. From planning, development and production to installation and commissioning. We produce your order picking system.