- Process visualisation in real time

- Intuitive information source

- Simple system integration via PLC

LED displays help with slide grinding

Advantages at a glance

The range of applications for valves is manifold, the demand for flawless surfaces always the same: Hoerbiger Kompressortechnik GmbH sets high standards for the valve components it produces. The valves are used in compressors for cooling and air-conditioning units, in compressed air applications in commercial vehicles or are installed in air compressors for trade and industry. There is no margin of quality in the surface quality of the valve components, especially the valve tongues. In order to monitor the actual status of the necessary vibratory grinding in real time, Hoerbiger uses a specific LED measured value display from microSYST. This not only visualises the necessary grinding process, but also makes a simple and effective contribution to employee safety.

Three-column layout ensures maximum clarity

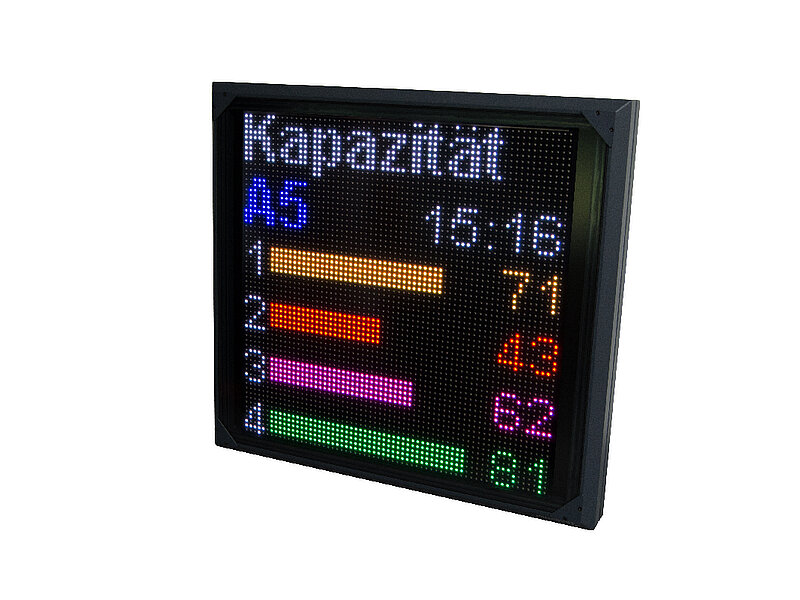

"By their very nature, vibratory finishing machines are very noisy, which is why they are housed in a closed room in our production facility," says Peter Schiessl, a technician in the control technology department at Hoerbiger Kompressortechnik GmbH, explaining the initial situation. In order to minimise the need for employees to enter the noise area, the company decided to visualise the machine statuses with the help of an LED display. The display is located outside the noise area at a height of about three metres and can thus be seen from all other production workplaces. The high-contrast LED modules ensure the necessary readability even from a greater distance. Three columns display all the necessary information: On the left, the machine number is displayed; in the middle column, a bar visualises the percentage of remaining runtime, supported by colour gradations depending on the progress. The right-hand column shows the remaining running time in hours and minutes. "Some of the grinding times are up to 14 hours. Via the display, our employees can record the remaining running times without having to enter the noise area and see when the next machine has to be emptied and refilled," says Schiessl. Even when changing shifts, the employees can find out about the current progress - virtually in passing. For an even more intuitive acquisition of information, it was decided to only show the central bargraph display when the machine in question is in operation. "This way, everyone can see at first glance which machines are currently running," Schiessl says again.

Ready for use via PLC

The LED display was manufactured and supplied by microSYST Systemelectronic GmbH according to the specific requirements of Hoerbiger Kompressortechnik. The pre-configured connection via a programmable logic controller worked without any problems. This receives the machine times via a bus system and also generates the bar charts from them. "The ready-to-use delivery without any necessary adjustment or programming work on site was a decisive point for us", Schiessl continues to be impressed.

Future-proof functionality

"Process monitoring and status control play a major role in the industrial working environment. With flexible display systems, we have been taking this area of application into account for many years and are familiar with the needs of manufacturing companies," emphasises Harald Kilian, microSYST owner and managing director. "In recent years, for example, there has been growing interest in additional functions such as acoustic signal tones or flashing in the event of special occurrences. Our in-house developed software is flexibly configurable in almost all directions here, so that the displays can grow with their tasks."