Using order picking systems efficiently and flexibly – many industrial sectors demand high standards of order picking systems. Especially small parts warehouses and picking areas, where pallets or containers systems such as small and large containers are used, require precise and flexible order picking systems.

Therefore, microSYST developed a light positioning system (LPOS) which combines flexibility, efficiency and variability within one system.

mipick LPOS - Light Position System

The benefits of our light positioning displays

- Light positioning displays for any application

Wether high-bay rackings, pallet storage locations or container systems – the light positioning displays can be mounted with lugs and also flexibly adjusted due to the variable direction of the spotlights. - Reduction of order picking errors

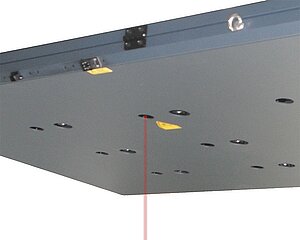

The goods as well as the places to be picked will be marked clearly with integrated lasers and spotlights – and order picking errors will be prevented. - Hands free during picking due to automatic acknowledgement

In combination with sensors such as light barriers, distance meters or scales you will be able to automate the acknowledgement process – for a fast and safe order picking process!

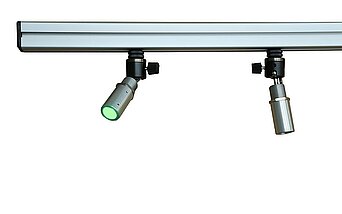

Positioning lasers and spots with adjustable beam direction

The light positioning system is equipped with laser pointers that can be adjusted in different directions by adjusting screws. Thus, the display is able to illuminate various picking areas - even if they may be located laterally - from a fixed central position.

Focus on various distances

The laser and spot beams can be focused even on various distances, depending on technology and type. This ensures glare-free illumination of the picking surfaces at all time at any desired operating site due to the system´s flexibility.

Contact us - we will be happy to advise you on the right choice of your light position indicator and supply you with the right product for your area of application!

Space-saving and barrier-free

The ceiling mount saves space and helps with keeping the workplace barrier-free. All other inventory is not affected. Additionally, no changes to current equipment are needed for installation.

Modular system setup

The modular system configuration of the mipick LPOS allows for the connection of several laser positioning systems and thus grants a flexible and easy way to adjust the system to the individual needs on site.

Application areas of Laser Positioning Systems

- Illumination of single / picking trays

- Controlling and supervisory monitoring e.g. in vehicle construction and engineering

- Visual guidance through process sequences e.g. for several work steps

- Universal use as process-accompanying display

| mipick LPOS | |||

with laser | with LED spots | ||

| Light source | Laser beam | LED spot | |

| Display colour | red other colours upon request | red, green, white, blue other colours upon request | |

| Quantity / Specification | Arbitrary / Laser Class 1 (<0,4 mW), Wavelength 650 nm | Arbitrary | |

Focus | Adjustable | ||

| Distance | depending on the technology and type (configured individually according to customer requirements) | ||

Data Input & Power Supply | |||

Data input | selectable: Ethernet TCP/IP, WLAN, | ||

| Operation voltage | 230 VAC / 50 Hz, 110 VAC / 60 Hz or 24 VDC ±20 % | ||

| Power consumption | approx. 0,15 W / laser + approx. 3,0 W for control electronics | approx. 4,0 up to 6,0 W/ spot depending on the colour + approx. 3,0 W for the control electronics | |

Housing & mounting | |||

| Housing | industrial version, powder coated aluminium | ||

Housing colour | RAL 7016 (anthracite) | ||

| Mounting | Mounting Holes in Upper Side of Housing | ||

Environmental conditions | |||

| Protection | Top/Sides: IP40 Bottom: IP10 (Light Opening) Upon request, a higher protection class is feasible | ||

Operating temperature | 0...+50 °C | ||

Storage temperature | -25...+70 °C | ||

Send Inquiry

Contact details

microSYST Systemelectronic GmbH

Am Gewerbepark 11

92670 Windischeschenbach

Germany